Fasteners and Machining: Improving the Manufacturing Process

Fasteners and Machining: Improving the Manufacturing Process

Blog Article

Browsing the World of Fasteners and Machining: Methods for Accuracy and Rate

In the detailed world of fasteners and machining, the mission for accuracy and rate is a perpetual difficulty that demands careful attention to information and critical preparation. From recognizing the varied variety of fastener kinds to picking optimal products that can hold up against strenuous demands, each action in the procedure plays a crucial duty in accomplishing the desired result. Accuracy machining techniques even more elevate the intricacy of this craft, requiring a delicate balance in between technological experience and innovative techniques. As we explore the techniques that can improve both speed and effectiveness in this domain, the interaction in between quality assurance actions and functional excellence arises as a vital centerpiece.

Understanding Fastener Kind

When picking fasteners for a project, understanding the various types available is vital for making certain optimal performance and reliability. Screws are utilized with nuts to hold products together, while screws are versatile bolts that can be made use of with or without a nut, depending on the application. Washing machines are necessary for distributing the lots of the fastener and avoiding damage to the material being secured.

Selecting the Right Products

Recognizing the importance of choosing the best materials is vital in guaranteeing the optimal performance and integrity of the chosen bolt kinds talked about formerly. When it involves bolts and machining applications, the product option plays a critical duty in establishing the total strength, durability, deterioration resistance, and compatibility with the intended setting. Different products use varying buildings that can considerably affect the efficiency of the fasteners.

Usual products utilized for fasteners consist of steel, stainless-steel, aluminum, titanium, and brass, each having its unique strengths and weaknesses. Steel is renowned for its high stamina and sturdiness, making it ideal for a vast array of applications. Stainless-steel uses outstanding rust resistance, perfect for atmospheres susceptible to moisture and chemicals. Aluminum is corrosion-resistant and lightweight, making it appropriate for applications where weight reduction is essential. Brass is typically picked for its visual allure and superb conductivity. Titanium is recognized for its outstanding strength-to-weight proportion, making it optimal for high-performance applications. Choosing the appropriate product entails thinking about factors such as toughness demands, environmental problems, and budget plan constraints to make sure the desired efficiency and durability of the bolts.

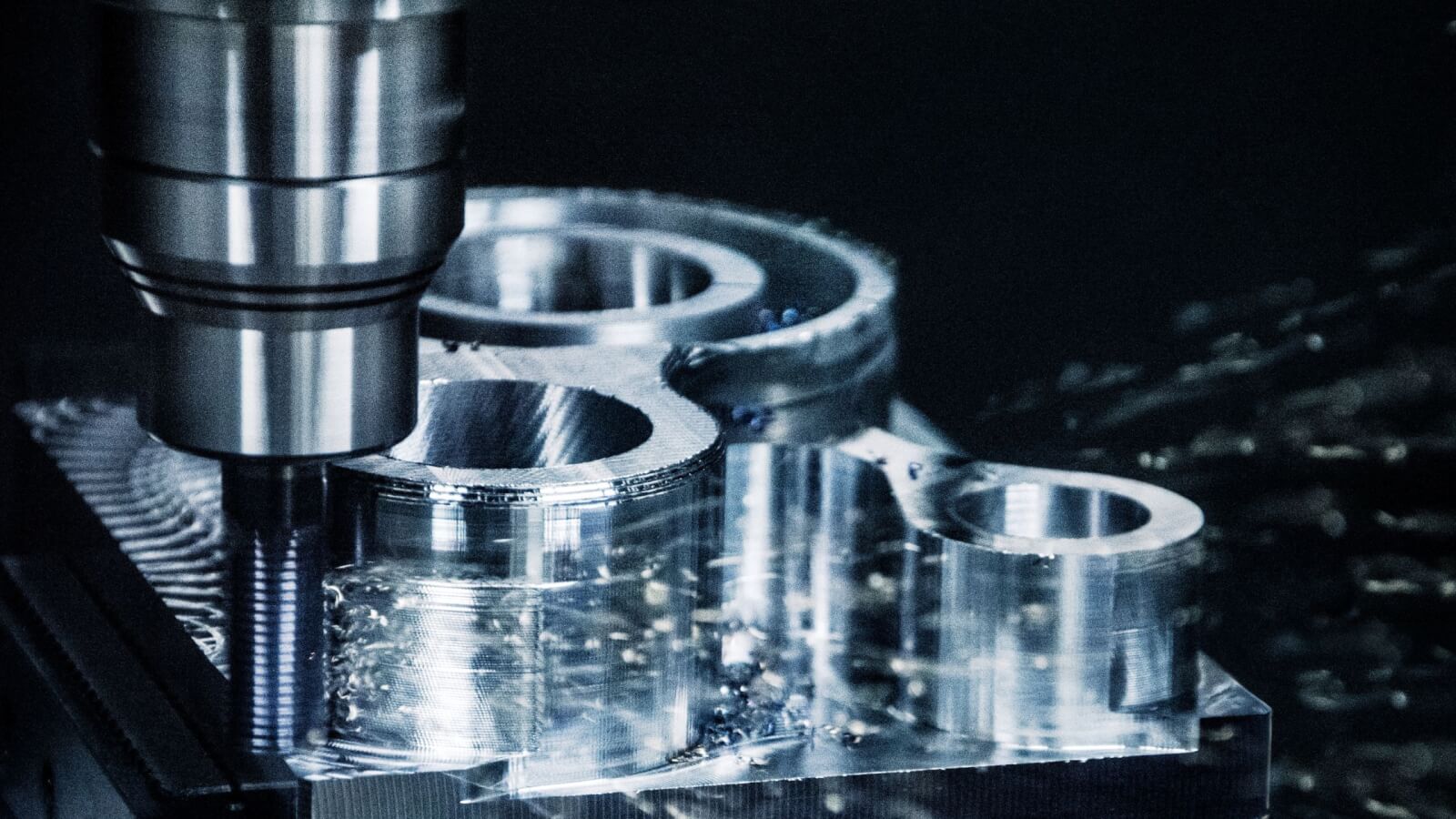

Accuracy Machining Techniques

Along with CNC machining, other accuracy methods like grinding, transforming, milling, and drilling play important roles in bolt production. Grinding helps attain fine surface area finishes and tight dimensional tolerances, while transforming is frequently utilized to develop cylindrical elements with specific sizes. Milling and drilling procedures are crucial for shaping and producing openings in bolts, guaranteeing they meet precise specs and feature correctly.

Enhancing Speed and Performance

To optimize bolt production processes, it is important to simplify operations and apply effective approaches that match accuracy machining techniques. Automated systems can take care of repetitive go to this site jobs with precision and rate, allowing workers to concentrate on more facility and value-added activities. By incorporating these techniques, manufacturers can achieve a balance in between speed and accuracy, inevitably enhancing their competitive edge in the bolt see here industry.

Quality Control Procedures

Applying rigorous quality assurance procedures is critical in making certain the reliability and consistency of fastener products in the manufacturing procedure. Quality assurance procedures include different stages, beginning with the choice of basic materials to the final evaluation of the ended up bolts. One fundamental aspect of quality control is performing thorough product inspections to verify conformity with requirements. This involves evaluating factors such as product toughness, structure, and toughness to ensure that the bolts fulfill industry standards. Furthermore, checking the machining processes is important to promote dimensional precision and surface coating quality. Utilizing advanced technology, such as computerized examination systems and accuracy measuring devices, can enhance the precision and performance of top quality control treatments.

Normal calibration of tools and machinery is vital to preserve uniformity in manufacturing and ensure that bolts meet the required tolerances. Executing stringent protocols for determining and attending to non-conformities or defects is essential in stopping substandard items from going into the marketplace. By developing a detailed high quality control framework, manufacturers can promote the online reputation of their brand name and supply bolts that satisfy the greatest requirements of performance and toughness.

Verdict

In the elaborate world of fasteners and machining, the mission for accuracy and speed is a perpetual obstacle that demands precise attention to detail and tactical planning. When it comes to fasteners and machining applications, the product option plays a vital duty in establishing the total toughness, longevity, deterioration resistance, and compatibility with the designated setting. Accuracy machining includes various advanced approaches that make certain the limited resistances and requirements required for fasteners.In addition to CNC machining, other accuracy strategies like grinding, transforming, milling, and boring play crucial functions in bolt manufacturing.To maximize fastener production processes, it is vital to simplify procedures and carry out reliable methods that match accuracy machining strategies.

Report this page